نوفمبر . 12, 2024 18:52 Back to list

slurry pump rubber parts factories

The Vital Role of Rubber Parts in Slurry Pumps

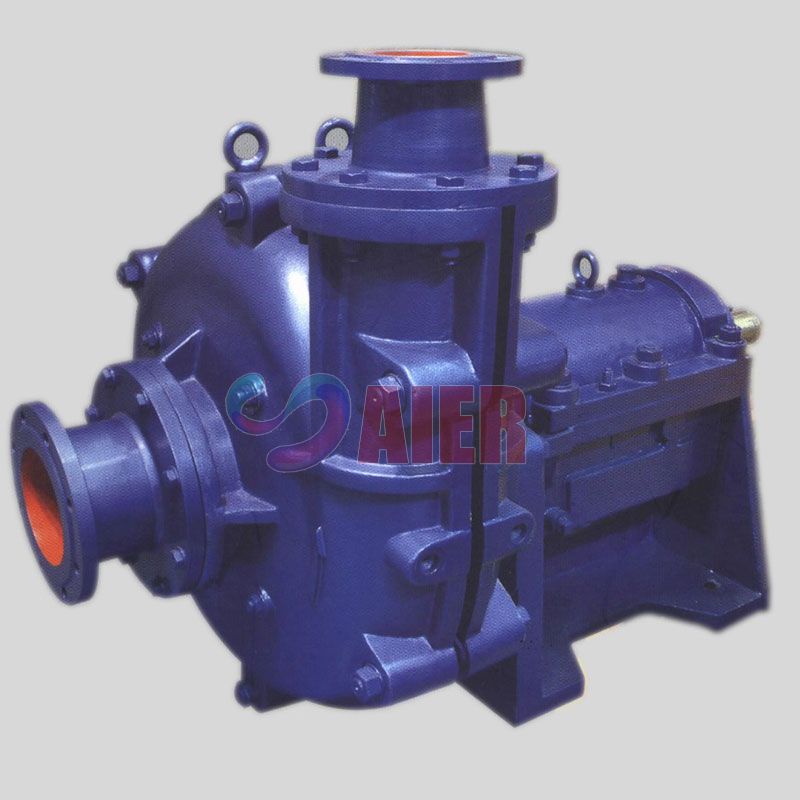

Slurry pumps play an integral role in various industries, including mining, construction, and wastewater management. One of the key components that contribute to the efficiency and longevity of these pumps is their rubber parts. In this article, we will explore the importance of rubber components in slurry pumps, the factors influencing their production in factories, and the future trends in this vital sector.

Understanding Slurry Pumps

Slurry pumps are designed to transport mixtures of liquid and solid particles, commonly referred to as slurries. These pumps are engineered to handle abrasive and corrosive materials, making them indispensable in environments where traditional pumps might fail. The effectiveness of a slurry pump largely hinges on its design, which includes various materials chosen for their ability to withstand harsh conditions.

The Importance of Rubber Parts

Rubber components, such as liners, impellers, and seals, are crucial to the operation of slurry pumps. Their primary functions include

1. Abrasion Resistance The abrasive nature of slurries can wear down pump components rapidly. High-quality rubber is designed to provide exceptional abrasion resistance, thus enhancing the pump's lifespan.

2. Chemical Resistance Slurries often contain chemically aggressive materials. Rubber parts are formulated with specific compounds that offer resistance to these chemicals, ensuring the integrity of the pump's functionality.

3. Flexibility and Sealing Rubber's inherent flexibility allows it to form tight seals, which is essential in preventing leaks. Effective sealing is vital not only for maintaining efficiency but also for ensuring safety in operations handling hazardous materials.

4. Vibration Damping Rubber has excellent vibration-damping properties. This is crucial in slurry pumps, as operational vibrations can lead to significant wear and tear over time. By absorbing these vibrations, rubber parts help extend the life of the pump.

The Manufacturing Process

Rubber parts for slurry pumps are manufactured in factories that specialize in polymer technology. The production process typically involves several stages

slurry pump rubber parts factories

1. Material Selection Different types of rubber, such as natural rubber, neoprene, or polyurethane, are selected based on the specific requirements of the slurry application.

2. Compounding The selected rubber is mixed with various additives to enhance its properties, including strength, elasticity, and chemical resistance.

3. Molding and Curing The compounded rubber is then molded into the desired shapes and cured to achieve the required hardness and durability.

4. Quality Control Rigorous quality control measures are implemented at various stages of production to ensure that the rubber parts meet industry standards.

Challenges Faced by Factories

While the demand for rubber parts in slurry pumps continues to grow, manufacturers face several challenges. One significant challenge is the need to continuously innovate to keep pace with advancements in pump technology. As slurry compositions evolve, so too must the materials used in rubber parts.

Additionally, environmental regulations pertaining to rubber production are becoming increasingly stringent. Factories must invest in sustainable practices, including reducing waste and minimizing emissions, to meet these requirements. The shift toward more environmentally friendly materials, such as bio-based rubbers, is also gaining traction within the industry.

Future Trends

The future of rubber parts in slurry pump manufacturing looks promising. With the rise of Industry 4.0, factories are increasingly adopting smart manufacturing technologies. Automation and data analytics can enhance production efficiency, reduce waste, and ensure consistent quality in rubber part manufacturing.

Moreover, research into advanced materials continues to drive innovation. For instance, the development of hybrid materials that combine the best properties of rubber with other materials could lead to even more durable and efficient slurry pump components.

Conclusion

In conclusion, rubber parts are essential to the performance and durability of slurry pumps. Their unique properties enable these pumps to handle the challenging conditions posed by slurries in various industries. As factories continue to innovate and adapt to new challenges, the role of rubber in slurry pump technology will undoubtedly remain vital, paving the way for more efficient and sustainable operations in the future.

-

Top Submersible Pump Companies High Quality Manufacturers & Suppliers in China

NewsJul.08,2025

-

High Quality Seal for 5 Inch Dredge Pump Reliable China Manufacturer & Supplier

NewsJul.08,2025

-

High-Efficiency Slurry Sand Pump from Leading China Manufacturer – Durable & Reliable Solutions

NewsJul.07,2025

-

High-Quality Slurry Pump Made in China Durable Steel Mill Slurry Pump & Parts

NewsJul.07,2025

-

High Quality Excavator Dredge Pump Manufacturer & Suppliers from China – Reliable, Durable, Efficient Solutions

NewsJul.07,2025

-

Wholesale Slurry Pump Closed Impeller Supplier High Efficiency China Slurry Pump Closed Impeller

NewsJul.06,2025