ديسمبر . 10, 2024 00:24 Back to list

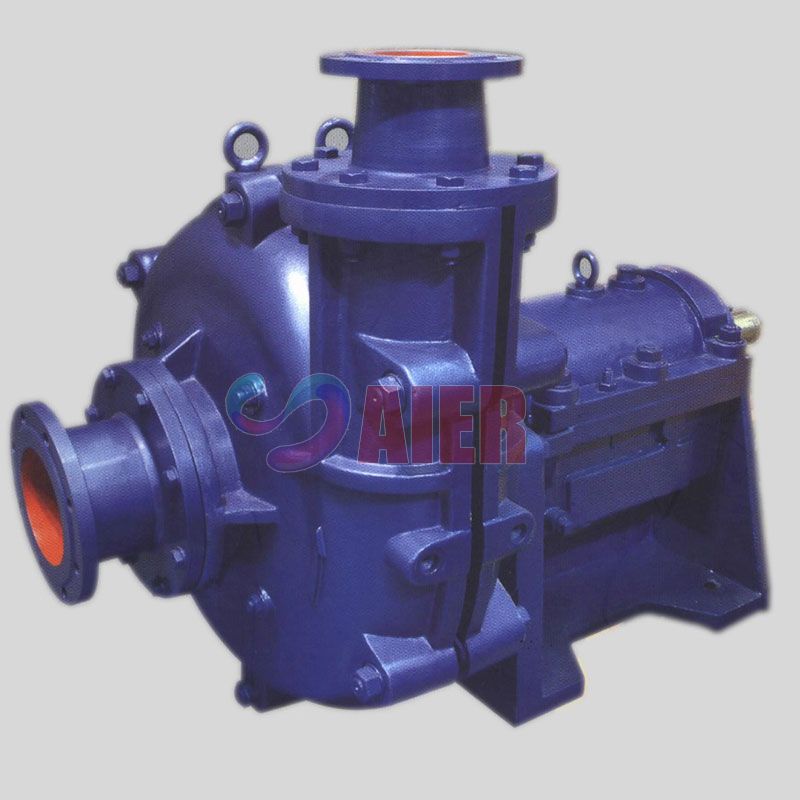

High-Performance Metallic Liner Slurry Pump Manufacturing Solutions for Various Industries

Metal Liner Slurry Pump Factory Ensuring Efficiency and Durability in Industrial Applications

In the realm of industrial processes, particularly in mining, mineral processing, and wastewater management, the need for reliable and efficient pumping solutions is paramount. One of the standout innovations in this area is the metal liner slurry pump, designed specifically to handle the abrasive and corrosive nature of slurry. A specialized factory dedicated to the production of these pumps plays a crucial role in ensuring that industries have access to robust and high-performance equipment to meet their operational demands.

Understanding Slurry Pumps

Slurry pumps are engineered for transporting a mixture of liquid and solid particles, commonly referred to as slurry. The nature of this mixture often includes materials like sand, coal, iron ore, clay, and various waste products. Unlike traditional pumps, slurry pumps must be constructed to withstand high levels of wear and tear due to the abrasive nature of the materials they transport. This is where the metal liner comes into play.

The Role of Metal Liners

Metal liners provide enhanced durability and resistance against corrosion and abrasion. These liners are typically made from high-grade metals such as stainless steel or other alloys, designed to extend the operational lifespan of the pumps significantly. The metal liner slurry pump’s design allows for efficient transportation of materials, reducing the risk of clogging and maximizing pump performance.

The Manufacturing Process

A factory specializing in metal liner slurry pumps employs advanced manufacturing techniques and rigorous quality control processes. The production typically involves several key stages

1. Design and Engineering Skilled engineers use computer-aided design (CAD) software to create models of the slurry pumps. Each pump is tailored to meet specific industry requirements, ensuring optimal performance.

metal liner slurry pump factory

2. Material Selection The choice of materials is critical in ensuring the durability of the pump. High-quality metals are selected based on their resistance to corrosion and wear.

3. Casting and Machining The selected materials undergo a casting process to form the basic shape of the pump components. Once cast, these parts are subjected to precise machining processes to achieve the required dimensions and surface finishes.

4. Assembly After machining, components are meticulously assembled. During this phase, attention to detail is essential to ensure that each pump functions as intended.

5. Quality Assurance Comprehensive testing is conducted to ensure that each pump meets industry standards. This includes pressure testing, performance testing, and inspections for potential leaks or defects.

Benefits of Using Metal Liner Slurry Pumps

The use of metal liner slurry pumps offers a multitude of advantages for industrial operations. First and foremost, their ability to handle abrasive materials with minimal wear means lower maintenance costs and reduced downtime. Additionally, the efficiency of these pumps contributes to overall operational productivity, allowing for smoother and faster processing of materials.

Moreover, metal liner slurry pumps are designed to operate in various challenging environments, making them versatile tools for a range of applications—from mining to wastewater treatment. Their robust construction ensures reliability even in the most demanding conditions.

Conclusion

As industries continue to seek reliable solutions for their pumping needs, factories that specialize in metal liner slurry pumps will remain integral to the supply chain. By focusing on quality manufacturing, innovative design, and effective performance, these factories not only meet the demands of today’s industrial landscape but also pave the way for future advancements in pumping technology. Investing in high-quality slurry pumps is not merely a choice; it is a strategic decision for companies aiming for efficiency, durability, and ultimately, success in their operations.

-

China SP Slurry Pump Supplier – Vertical Sump Pump Rubber Lined Manufacturer & Factory

NewsJul.05,2025

-

High Quality Submersible Slurry Pump with Agitator Manufacturer & Factory Reliable Submersible Pump Solutions

NewsJul.05,2025

-

Cheap Dredge Pump for Sale – China Cheap Submersible Pump for Wastewater Supplier

NewsJul.05,2025

-

Wholesale Casting Dredge Pump Part - High Quality China Manufacturers & Suppliers

NewsJul.04,2025

-

High Quality Slurry Pump Seals Reliable China Suppliers & Manufacturers

NewsJun.24,2025

-

High Quality Portable Submersible Slurry Pump Supplier & Manufacturer from China

NewsJun.10,2025