ነሐሴ . 01, 2024 01:36 Back to list

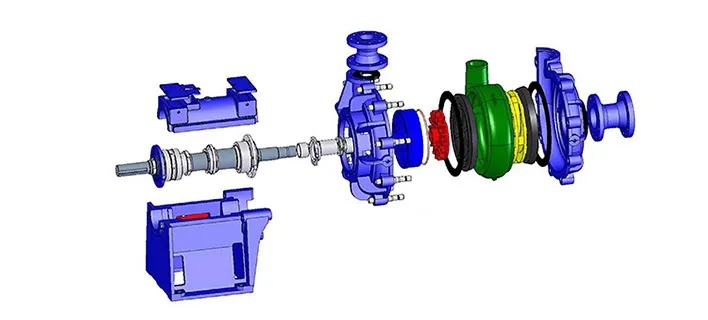

Warman Slurry Pump Replacement Parts and Accessories for Enhanced Performance and Durability

Understanding Warman Slurry Pump Spares Essential Components for Optimal Performance

Warman slurry pumps are renowned in the industrial sector for their ability to handle abrasive and corrosive materials effectively. Used extensively in mining, mineral processing, and wastewater management, these pumps are critical for transporting slurry, which is a mixture of liquid and solid particles. To ensure that Warman slurry pumps operate at peak efficiency, it is essential to have a thorough understanding of their spare parts. This article explores the significance of Warman slurry pump spares, highlighting their roles, types, and maintenance importance.

Importance of Spare Parts

Spare parts are crucial for the longevity and efficiency of Warman slurry pumps. Over time, components can wear out due to the abrasive nature of the materials they handle. If a pump is not properly maintained, it can lead to reduced performance, increased energy consumption, and even catastrophic failures. Having the right spare parts readily available minimizes downtime and ensures that operations run smoothly.

Moreover, utilizing genuine Warman spare parts is essential. These parts are designed specifically for Warman pumps and are manufactured to meet exact specifications. Non-genuine parts may appear to be a cost-saving option, but they can lead to inefficiencies and increased wear, ultimately costing more in the long run due to frequent replacements and potential damage to other components.

Key Spare Parts for Warman Slurry Pumps

1. Impellers The impeller is a critical component of the slurry pump, responsible for converting rotational energy into hydraulic energy. Over time, impellers can wear down, leading to reduced flow rates and increased power consumption. Regular inspection and timely replacement of impellers are essential to maintain pump performance.

2. Casing The casing houses the impeller and provides a pathway for the slurry to flow through the pump. The casing can also wear due to abrasive materials. High-quality casings made from durable materials, such as rubber or hard metals, can significantly prolong the lifetime of the pump.

3. Suction and Discharge Flanges These flanges connect the pump to the piping system. They must be inspected regularly for wear and corrosion. Replacing flanges at the first sign of distress can help prevent leaks and ensure efficient operation.

warman slurry pump spares

4. Mechanical Seals These seals prevent slurry from leaking out of the pump. Worn or damaged seals can lead to contamination and reduced efficiency. Regular maintenance and replacement are crucial for maintaining operational integrity.

5. Bearings Bearings support the rotating shaft of the pump. If they wear out, they can lead to misalignment and further damage to other components. Choosing high-quality bearings and replacing them as needed is vital for the reliability of the pump.

Maintenance Best Practices

Regular maintenance is key to ensuring the longevity of Warman slurry pumps and their spare parts. Here are some best practices

- Routine Inspections Implement a schedule for regular inspections of all critical components. Early detection of wear can prevent more significant issues down the line.

- Proper Lubrication Ensure that bearings and other moving parts are adequately lubricated to reduce friction and wear.

- Use Genuine Parts Whenever replacement is necessary, always opt for genuine Warman spare parts. This ensures compatibility and reliability.

- Training and Awareness Ensure that personnel operating and maintaining the pumps are properly trained on their operation and care. Awareness can lead to proactive measures that extend the pump's life.

In conclusion, understanding the importance of Warman slurry pump spares is vital for maintaining optimal performance and efficiency in operations that rely on slurry transport. By prioritizing the quality of spare parts and committing to regular maintenance, industries can significantly enhance the reliability and lifespan of their pumps, leading to smoother operations and reduced costs.

-

Wholesale Casting Dredge Pump Part - High Quality China Manufacturers & Suppliers

NewsJul.04,2025

-

High Quality Slurry Pump Seals Reliable China Suppliers & Manufacturers

NewsJun.24,2025

-

High Quality Portable Submersible Slurry Pump Supplier & Manufacturer from China

NewsJun.10,2025

-

Slurry Pump Parts Manufacturer – High Quality Rubber Spare Parts from China

NewsJun.10,2025

-

High Quality 1/3 HP Submersible Sump Pump with Vertical - Reliable Supplier & Factory Price

NewsJun.10,2025

-

High-Efficiency Centrifugal Slurry Pumps India

NewsJun.10,2025