ኅዳር . 11, 2024 22:05 Back to list

high quality slurry pump wet end parts factories

High-Quality Slurry Pump Wet End Parts A Comprehensive Overview

In industries where abrasive materials and slurries are handled, robust equipment is crucial for operational efficiency. Among the essential components of slurry pumps are the wet end parts, which are responsible for the movement of the slurry. High-quality slurry pump wet end parts are imperative to ensure longevity, performance, and reliability. This article delves into the significance of these components, their manufacturing processes, and how to select high-quality suppliers.

Understanding Slurry Pump Wet End Parts

Wet end parts of a slurry pump are crucial components that come into direct contact with the slurry. They are designed to withstand the harsh conditions typical of slurry applications, such as high wear, corrosion, and extreme temperatures. Key elements of the wet end include

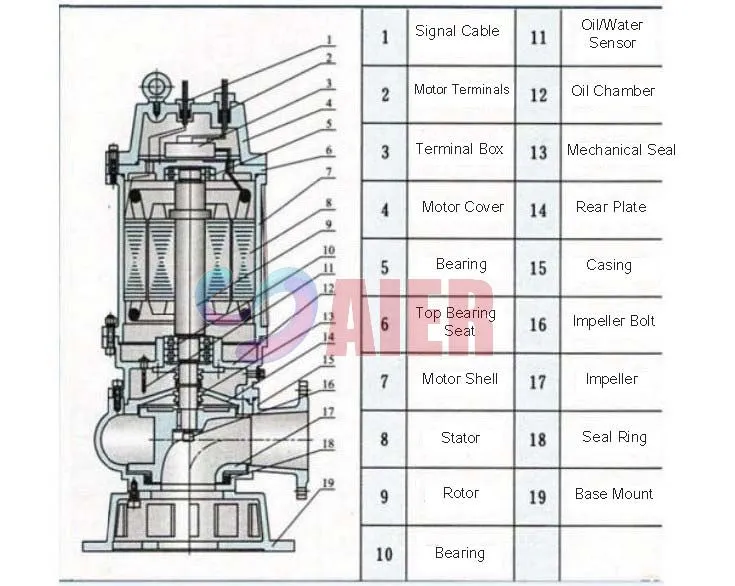

1. Impellers These are rotating components that transfer energy to the slurry, enabling it to move through the pump. Impellers must be designed with precision to provide optimal flow and efficiency.

2. Volute Liners The volute is the casing that contains the impeller. Lining materials, often made from wear-resistant metals or rubber compounds, protect the volute from abrasive wear.

3. Suction Housings The suction side of the pump must efficiently draw slurry into the pump without causing air entrainment, which can lead to cavitation and reduced performance.

4. Seals and Gaskets These components prevent leakage and protect sensitive parts from the corrosive nature of the slurry. High-quality seals are vital for the longevity of the pump.

5. Wear Plates These plates are installed to absorb wear and protect the main body of the pump from abrasive particles in the slurry.

Manufacturing High-Quality Wet End Parts

The production of high-quality wet end parts involves advanced manufacturing techniques and materials. Some of the methods included are

- Casting Many wet end components, particularly the impellers and volute liners, are manufactured through casting processes

. High-grade alloys are selected to ensure durability and resistance to wear.- Machining After casting, parts often undergo precision machining. This step ensures that components fit together flawlessly, optimizing efficiency and reducing maintenance needs.

high quality slurry pump wet end parts factories

- Heat Treatment Treating materials under controlled conditions enhances their hardness and wear resistance, making them suitable for the harsh environments they will face.

- Quality Assurance Rigorous testing and quality control are implemented throughout the manufacturing process. Components are checked for dimensional accuracy, material integrity, and performance under simulated operational conditions.

Selecting Suppliers for Wet End Parts

Choosing the right supplier for slurry pump wet end parts is critical for ensuring operational efficiency. Here are several factors to consider when selecting a manufacturer or supplier

1. Reputation and Experience Look for companies with a track record in producing high-quality slurry pump components. Check reviews, testimonials, and case studies to understand their experience in the industry.

2. Material Quality Ensure that the supplier uses high-grade materials designed specifically for slurry applications. Inquire about the types of alloys and their properties.

3. Customization Options Depending on the specific requirements of your operation, you may need customized parts. A good supplier should offer customization services to meet your unique needs.

4. Testing and Validation Suppliers should perform thorough testing on their products. Ask about their quality assurance protocols and if they can provide test reports.

5. After-sales Support Reliable suppliers offer after-sales support, including troubleshooting, maintenance advice, and service contracts. This support can be invaluable in navigating challenges that arise during operation.

6. Pricing and Delivery Compare prices among different suppliers, but prioritize quality over cost. Timely delivery is also crucial, especially in industries where downtime can lead to significant financial loss.

Conclusion

High-quality slurry pump wet end parts are vital for the efficient handling of slurries in various industries, from mining to wastewater management. By understanding the key components, manufacturing processes, and criteria for selecting suppliers, companies can ensure they invest in the right equipment to enhance productivity, reduce maintenance costs, and improve overall operational efficiency. When it comes to managing abrasive materials, choosing the right wet end parts will make all the difference.

-

Top Submersible Pump Companies High Quality Manufacturers & Suppliers in China

NewsJul.08,2025

-

High Quality Seal for 5 Inch Dredge Pump Reliable China Manufacturer & Supplier

NewsJul.08,2025

-

High-Efficiency Slurry Sand Pump from Leading China Manufacturer – Durable & Reliable Solutions

NewsJul.07,2025

-

High-Quality Slurry Pump Made in China Durable Steel Mill Slurry Pump & Parts

NewsJul.07,2025

-

High Quality Excavator Dredge Pump Manufacturer & Suppliers from China – Reliable, Durable, Efficient Solutions

NewsJul.07,2025

-

Wholesale Slurry Pump Closed Impeller Supplier High Efficiency China Slurry Pump Closed Impeller

NewsJul.06,2025