Des . 05, 2024 18:18 Back to list

High Efficiency High Pressure Pumps for Detergent Slurry Manufacturing Solutions

High-Quality High-Pressure Pumps for Detergent Slurry Factories

In the world of industrial manufacturing, the need for efficient and reliable pumping systems is paramount, especially in sectors dealing with viscous fluids such as detergent slurries. High-quality high-pressure pumps play a crucial role in the production of detergents, contributing significantly to operational efficiency and product quality.

Importance of High-Quality Pumps

Detergent production involves blending various raw materials, including surfactants, solvents, and additives, into a cohesive slurry. This process often requires the movement of complex mixtures under high pressure to ensure thorough mixing, consistent quality, and efficient processing. High-pressure pumps designed specifically for this purpose can considerably enhance the operational capabilities of detergent slurry factories.

High-quality pumps are engineered to handle the challenges posed by the physical and chemical properties of detergent slurries. The viscous nature of these mixtures demands pumps that can maintain consistent flow rates while operating under significant pressure. Additionally, the corrosive nature of some detergent ingredients necessitates pumps made from durable, corrosion-resistant materials to ensure longevity and reliability.

Key Features of High-Pressure Pumps

When selecting a high-pressure pump for detergent slurry production, several critical features should be considered

1. Material Construction Pumps should be constructed from materials like stainless steel or special alloys that can withstand corrosive environments. This is vital for maintaining pump integrity and performance over an extended lifespan.

2. Pressure Rating A suitable high-pressure pump should be capable of handling the required pressure ranges specific to the detergent manufacturing process. Pumps with adjustable pressure settings allow for flexibility in operation, accommodating various formulations.

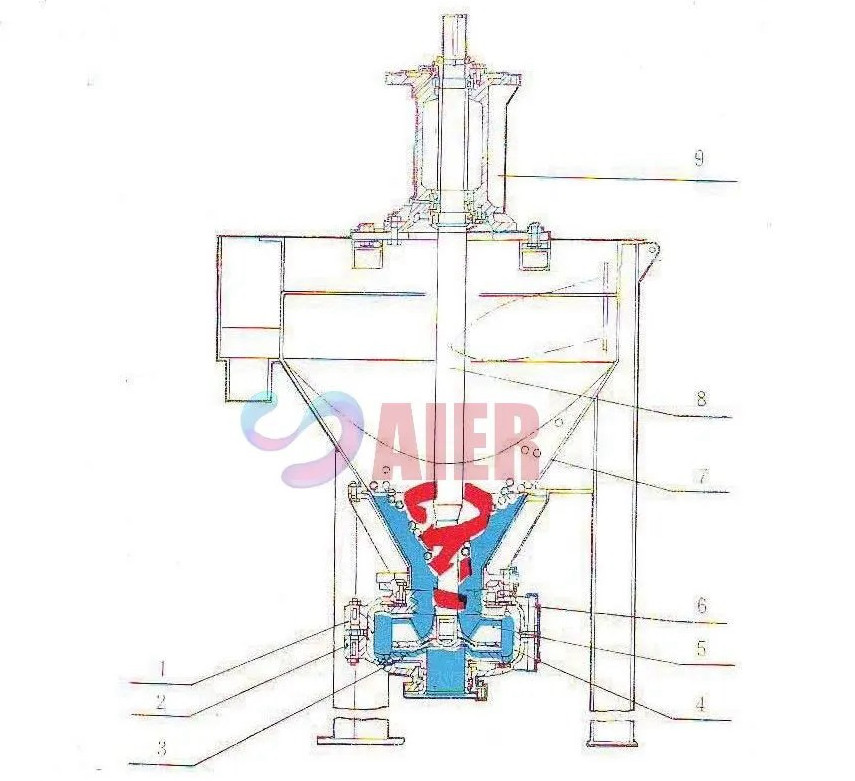

high quality high pressure pump for detergent slurry factories

3. Flow Rate Versatility The ability to adjust flow rates is essential in detergent production, as different products may require varying speeds. Pumps that offer variable frequency drives (VFD) can efficiently modulate flow rates without sacrificing pressure.

4. Ease of Maintenance High-quality pumps should be designed for easy maintenance to minimize downtime. Features like quick-disconnect fittings and accessible internal components can significantly reduce the time and labor involved in service.

5. Energy Efficiency As energy costs continue to rise, investing in energy-efficient pump systems can result in substantial cost savings. High-quality pumps often incorporate technologies designed to reduce energy consumption while maintaining high performance.

Applications in Detergent Production

In detergent slurry factories, high-pressure pumps are utilized in several key areas, including

- Ingredient Transfer Efficiently moving raw ingredients from storage to blending tanks. - Mixing Processes Ensuring uniformity in the product by maintaining the necessary pressure during the blending phases. - Packaging Assisting in the transfer of finished products into containers with precision and speed.

Effective pump selection directly influences the quality of the final product, as inconsistencies in mixing or ingredient transfer can lead to variations that affect performance and customer satisfaction.

Conclusion

Investing in high-quality high-pressure pumps is paramount for detergent slurry factories aiming to enhance their operational efficiency and product quality. By selecting pumps that meet the specific demands of detergent production, manufacturers can not only optimize their processes but also gain a competitive edge in a challenging market. The combination of robust construction, advanced technology, and adaptable features ensures that these pumps can meet the ever-changing needs of the detergent industry, paving the way for innovation and growth.

-

Top Submersible Pump Companies High Quality Manufacturers & Suppliers in China

NewsJul.08,2025

-

High Quality Seal for 5 Inch Dredge Pump Reliable China Manufacturer & Supplier

NewsJul.08,2025

-

High-Efficiency Slurry Sand Pump from Leading China Manufacturer – Durable & Reliable Solutions

NewsJul.07,2025

-

High-Quality Slurry Pump Made in China Durable Steel Mill Slurry Pump & Parts

NewsJul.07,2025

-

High Quality Excavator Dredge Pump Manufacturer & Suppliers from China – Reliable, Durable, Efficient Solutions

NewsJul.07,2025

-

Wholesale Slurry Pump Closed Impeller Supplier High Efficiency China Slurry Pump Closed Impeller

NewsJul.06,2025